News and Information

2024-08-12

Hangzhou Chuankong

287

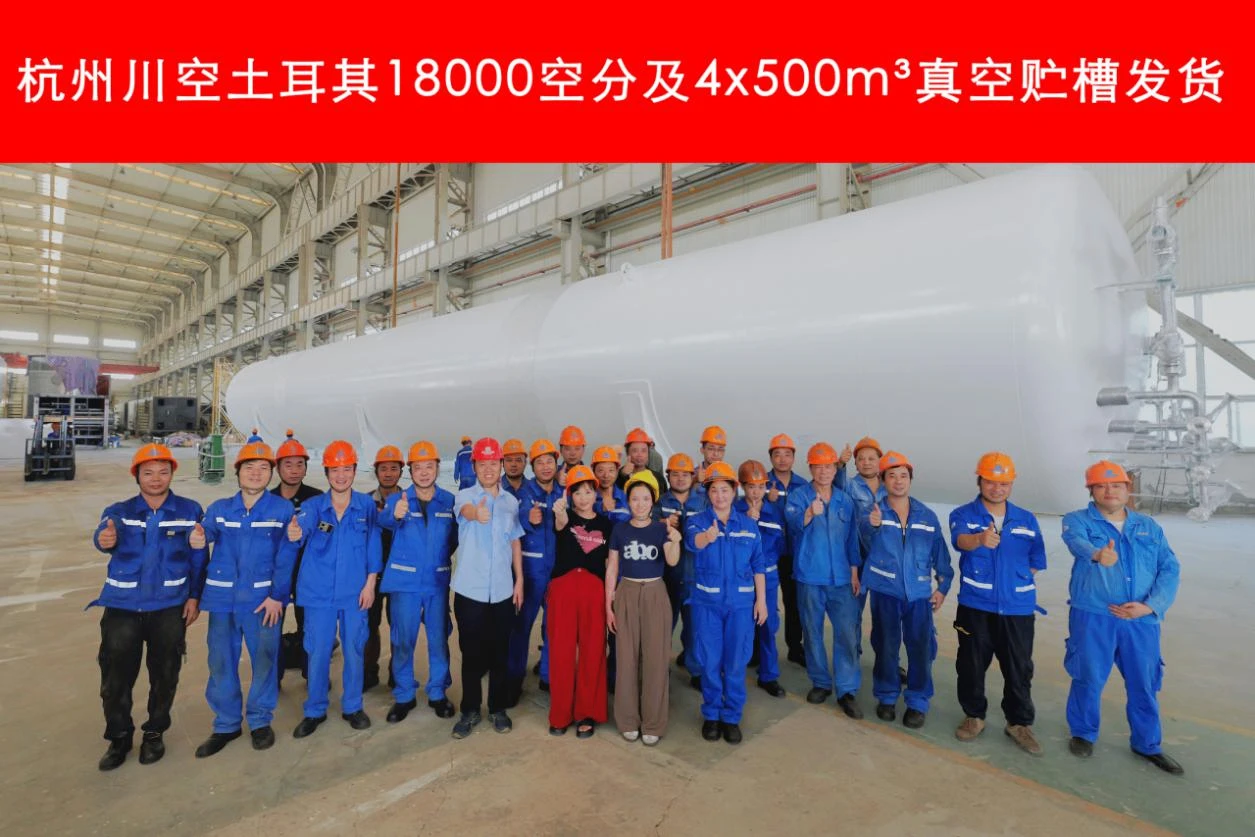

On August 6, 2024, the skid-mounted cold box and four sets of 500m³ vacuum storage tank for the Turkish Copper Plant project were successfully loaded and shipped. This achievement was made possible through the dedicated efforts of the production department and frontline workshop employees, who braved the intense summer heat and worked tirelessly with extra shifts under the leadership of company management.

This project involved an 18,000 Nm³/h ASU exported by Sichuan Air Separation Plant Group to a Turkish copper plant. Zhejiang Dachuan was responsible for the design and manufacturing of the skid-mounted (with argon) cold box and four sets of 500 m³ vacuum storage tank. The equipment was required to comply with ASME standards and CE certification, reflecting stringent quality requirements. As the first-of-its-kind product for Zhejiang Dachuan, its manufacturing was scheduled alongside the 60,000 Nm³/h ASU cold box for another Turkish project. To optimize time and space, the production department and workshop developed a detailed material input and manufacturing plan, striving to accelerate progress. Material input began in early April, with workshop teams working extra shifts and maintaining 24/7 non-stop operations—where the equipment never stopped, even when shifts changed. Due to space constraints, the installation of the 18,000 Nm³/h ASU for the Turkish copper plant did not begin until June 8. Under the coordination of Zhejiang Dachuan’s management, cross-functional operations were organized: one team worked on the cold box shell, another on equipment positioning, and a third on pipeline installation. The cold box was assembled and pressure-tested by July 16. The four sets for 500 m³ vacuum storage tanks began sleeve-assembling on June 28. Subsequent steps included pre-vacuuming, perlite filling, vacuum extraction, valve installation, pressure testing, and painting. To ensure on-time delivery, assembling was conducted simultaneously in two workshops: half of the work was done in No. 1 Workshop before transferring to No. 2 Workshop. Through continuous day-and-night efforts and 24-hour non-stop operations, all processes were completed, and the products were delivered as scheduled.

The successful delivery of this project is a testament to the extraordinary efforts of all production and manufacturing personnel at Zhejiang Dachuan, who broke conventional patterns, tackled challenges with determination and full commitment, and ultimately ensured the on-time shipment of the cold box and storage tanks for the Turkish copper plant. This achievement provides strong support for the SASPG Group's export operations.